Kalamazoo, Michigan, United States

Harbor Farmz

Located east of Lake Michigan, just off I-94 in Kalamazoo, Harbor Farmz is on a mission to bring the Michiganders spirit of care and craftsmanship to cannabis.

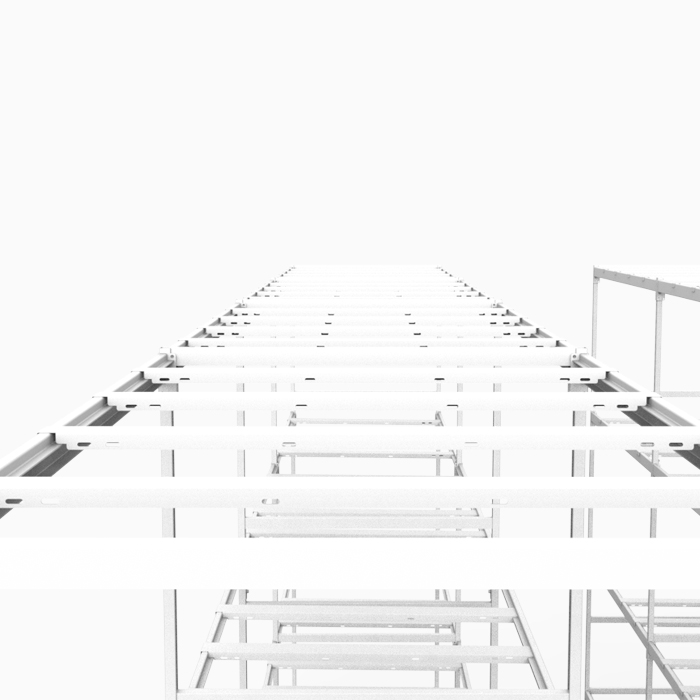

Vertical Grow Racks

Montel's GROWRAK™ 2.0 was engineered to free up space between frames, providing plenty of clearance for better airflow, ventilation ducts, lighting fixtures and oversize trays.

DISCLAIMER : The laws regarding indoor cannabis farming may differ from one area to another. In certain cases, exemptions are available for industrial, medical and / or agricultural purposes. Therefore, we urge you to look into international, federal, state and/or local laws. We legally supply our indoor farming systems and provide them solely to clients who are authorized to grow cannabis.

Request information now

Montel’s GROWRAKTM 2.0 system is ideal for vertical farming applications and engineered for Montel’s GREENRAK® 2.0 and GROW&ROLL® 8MA mobile grow systems.

The sleek, smooth finish of the uprights minimize cut-edge corrosion, and are built without holes on two faces of the frames for easier cleaning and bacteria prevention.

NO DIAGONAL BRACING OPTIMIZES AIRFLOW:

For better airflow, the diagonal upright frame bracing has been replaced with horizontal bracing, though there is enough spacing for oversize or infinite trays to pass through the upright frames. (Note: Diagonal bracing may be required in some instances.)

Custom bracing provides clearance between each level for greater airflow and accommodates ventilation system ducts, lighting fixtures, and other utilities. The bottom horizontal frame bracing can also be customized to provide the desired clearance for pipes, fittings, and other utilities just above floor level.

STANDING WATER PREVENTION:

The beams are designed to minimize standing water, and the inverted reinforcements on the optional wire mesh decking prevents standing water.

The beams are adjustable at 2” (5.08 cm) increments and lock safely into the tapered holes of the upright frames. The strong welded uprights facilitate the assembly process.

FLUSH OR SLOPED UNIVERSAL SUPPORTS:

The front-to-back flush or sloped universal supports are designed to accommodate trays and hang lighting fixtures.

The inclined supports allow for easy drainage:

The front-to-back universal supports integrate seamlessly with LED lights and allow for various lighting attachment positions. Brackets and mounting hardware are available to hang numerous models of LED light fixtures and Montel’s built-in LoopAir® 2.0 dual ventilation system (patent pending).

WIRE MESH DECKING:

In lieu of front-to-back supports to accommodate trays, hang lighting, or attach other utilities, you may opt for wire mesh decking. The wire mesh decking provides numerous possibilities for LED lighting attachment. The wire mesh decking is designed with upside-down reinforcements to eliminate standing water.

POWDER-COATED WHITE PAINT:

GROWRAKTM 2.0 is finished with an ultra-reflective antimicrobial powder-coated white paint approved by the FDA.

We would love to connect!