Strengthen Your Supply Chain with Montel’s High-Density Storage Solutions

Insights on storage - April 23rd 2025

Supply chain disruptions can strike from any direction—cyberattacks, logistical challenges, or natural disasters. While each disruption is unique, the impact on businesses is often the same: higher costs and reduced customer satisfaction. Montel’s high-density mobile racking systems can help you build a more resilient supply chain through better space management, allowing you to weather the unexpected while maintaining efficiency.

The Hidden Costs of Supply Chain Disruptions

Supply chain disruptions can force businesses to rely on more expensive suppliers or warehousing solutions, but the real losses come from missed opportunities. A study estimated that global businesses miss out on $1.6 trillion in potential growth revenue due to disruptions.

- Increased Costs: Pivoting to alternate suppliers or logistics increases operational expenses.

- Lost Revenue Opportunities: With each disruption, companies risk missing out on new market opportunities, impacting long-term growth.

Customer Satisfaction: The Unseen Casualty of Disruptions

On average, a single supply-chain disruption can decrease sales by 7%. Regaining lost customer trust and market share is a challenging process, and the cost of winning back customers can be substantial. The question for supply chain managers is clear: How can better inventory management help safeguard customer satisfaction?

Just-in-Time vs. Just-in-Case: Choosing the Right Inventory Strategy

You can’t control external disruptions, but you can control how you manage your warehouse space. More companies are shifting from just-in-time (JIT) to just-in-case (JIC) inventory models:

- Just-in-Time Inventories (JIT): This lean stocking approach helps to keep operating costs low but can make businesses more vulnerable during supply chain interruptions.

- Just-in-Case Inventories (JIC): By keeping extra inventory of essential materials or finished goods, businesses can maintain continuity during disruptions.

Whether you favor JIT or JIC, each strategy requires efficient use of space. High-density storage solutions can help you manage inventory fluctuations and optimize your warehouse operations.

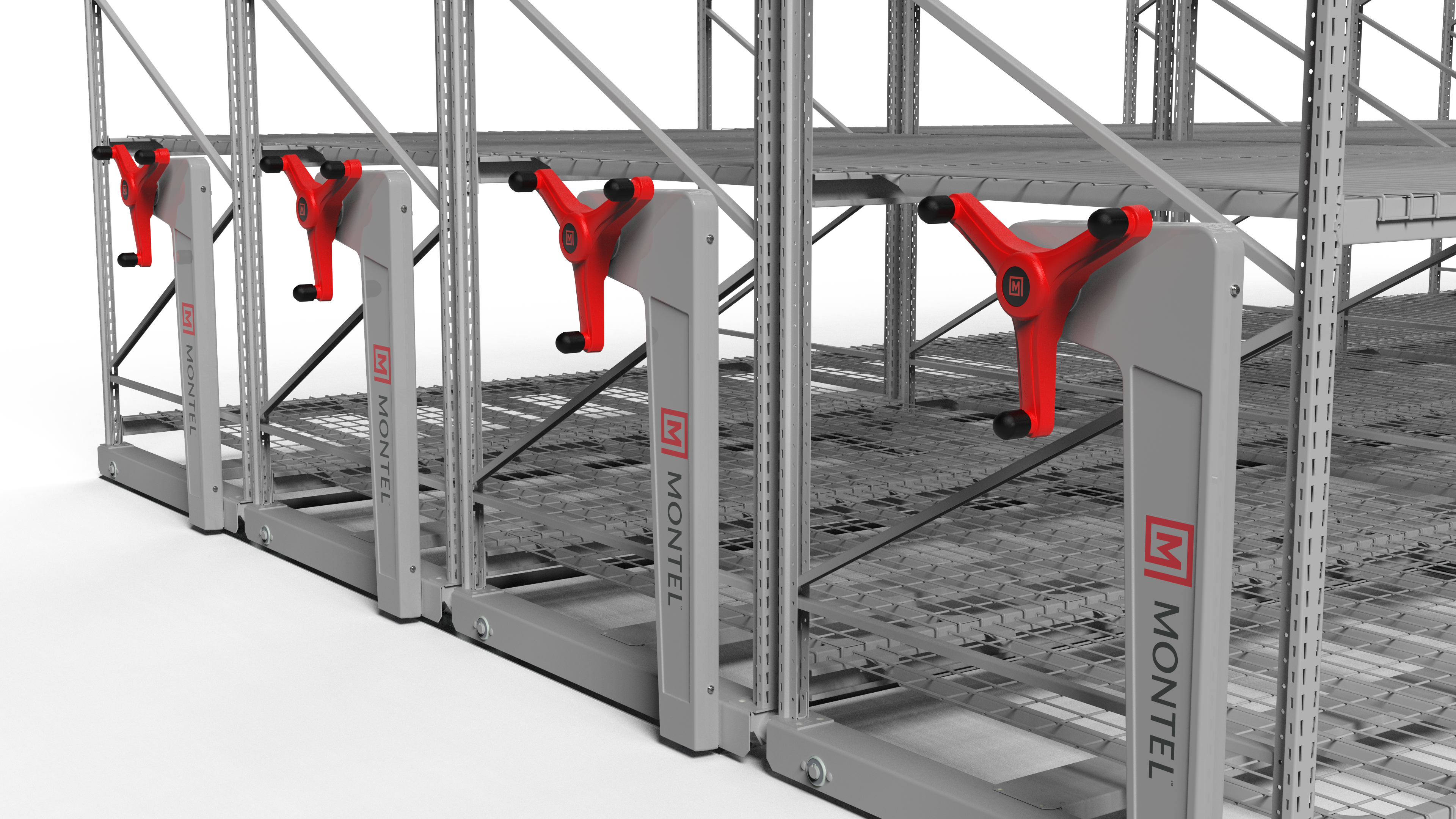

High-Density Mobile Racking: Your Key to Supply-Chain Resilience

By eliminating fixed aisles, high-density mobile racking systems from Montel can increase storage capacity by up to 50%, allowing your warehouse to adapt quickly to changes in inventory needs. This flexibility means you can store additional emergency inventory or reduce operational costs without compromising on storage efficiency.

- Increase Storage Capacity: Store more without expanding your footprint.

- Adapt to Market Changes: Respond to disruptions with the flexibility to stock more inventory when needed.

- Lower Operational Costs: Efficiently manage space to keep costs down, even with a just-in-case inventory approach.

Real-World Success: Montel’s Impact on Supply Chains

Montel has partnered with leading companies to improve their inventory management and warehouse efficiency:

- Airbus: Improved space utilization through customized high-density racking.

- Miller Industries: Streamlined storage solutions for better inventory control.

- Perrigo: Optimized warehouse operations with high-density storage systems, enhancing their supply chain resilience.

Future-Proof Your Warehouse: Contact Montel Today

Don’t let space constraints limit your ability to respond to supply-chain disruptions. Partner with an Authorized Montel Distributor for a free, no-obligation consultation and learn how our high-density storage solutions can make your warehouse a pillar of resilience and efficiency.