Kalamazoo, Michigan, United States

Harbor Farmz

Located east of Lake Michigan, just off I-94 in Kalamazoo, Harbor Farmz is on a mission to bring the Michiganders spirit of care and craftsmanship to cannabis.

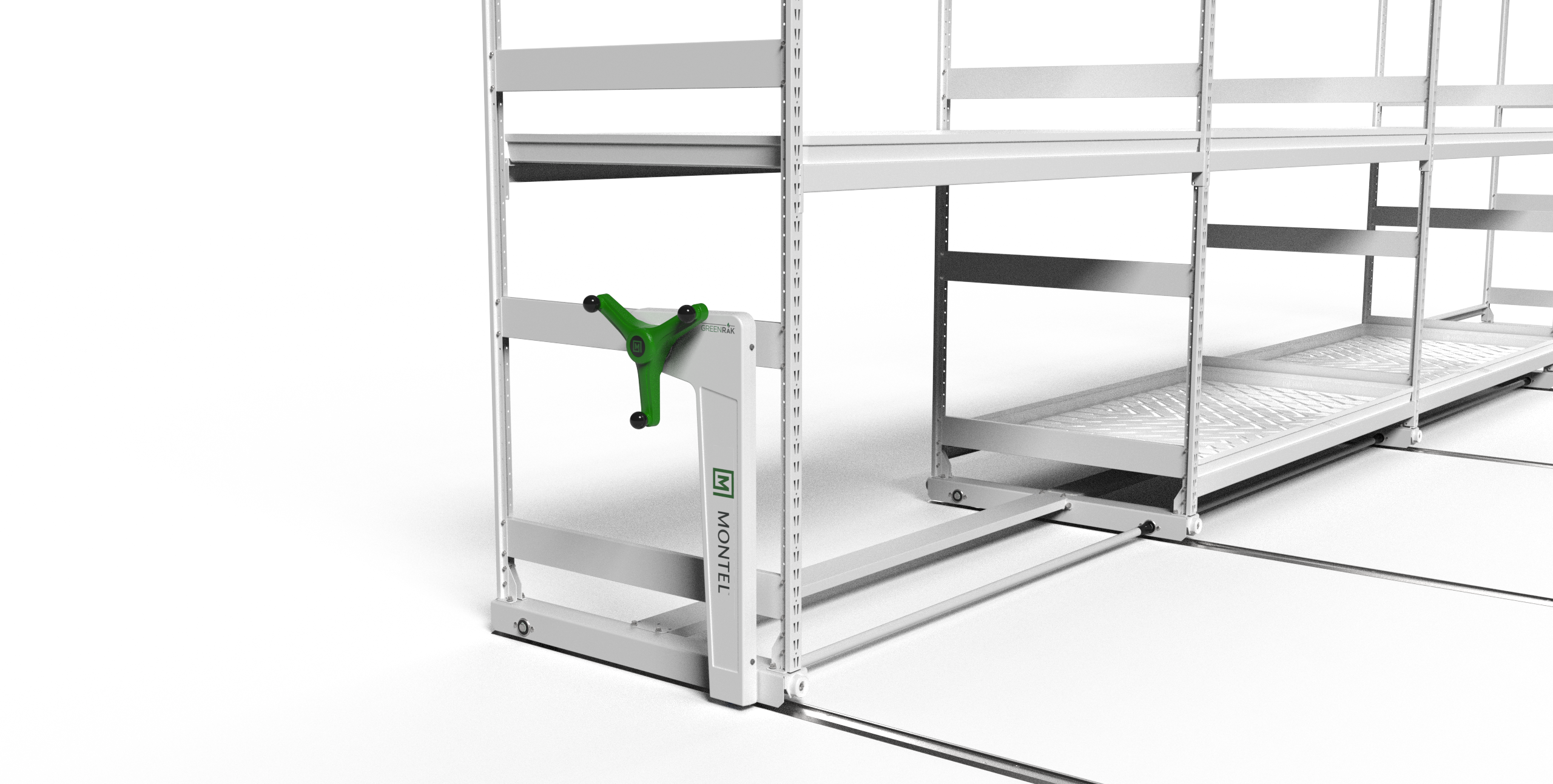

Mobile Storage Systems

Developed specifically for your indoor grow operation, the GREENRAK 2.0™ mobile system is lightweight, resistant to rust, and simple in design, which allows for easy installation, use, and maintenance.

Request information now

Why a trolley mobile system is better than a carriage mobile system for your mobile vertical farm.

Montel’s GREENRAK® 2.0 mechanical-assist mobile system is designed for high-density vertical multi-level indoor farming of leafy greens, micro greens, cannabis or any other controlled environment agriculture.

Receive a proposal in less than 48 hours

Share your room layouts and dimensions with us and get a no-obligation FREE design analysis, including 2-D and 3-D renderings, pricing and ROI.